-

x

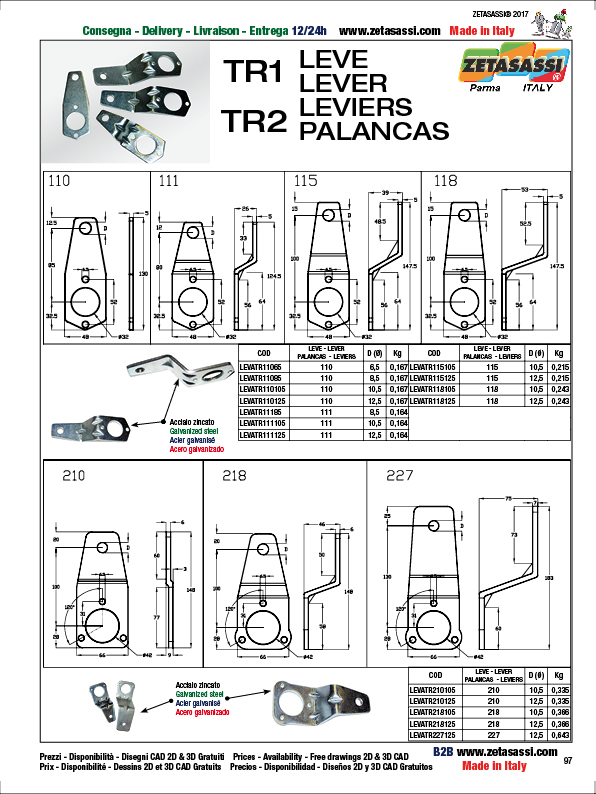

LEVER TR2 218 FOR ROTARY DRIVE TENSIONER - HOLE Ø12,5mm

Description

The versatility of the TR models is due to the possibility to change the load lever so as to reach any height without losing in rigidity. They have interchangeable 110,111,115,118 levers for the type 1 and 210,218,227 levers for the type 2.

AUTOMATIC ROTATING AND ROTARY SPRING-ACTION TENSIONERS

TR rotary tensioners are automatic devices that serve to maintain the correct tension of the transmission chain or belt, thereby increasing their durability.

They automatically recover any slack in the chain or belt that may develop with use, preventing the appearance of vibrations, noise and breakage due to slack.

These automatic tensioners do not require any kind of upkeep and make it possible to save time on maintenance and management of the machinery on which they are installed.

The TR1 and TR2 models consist of a base and lever in special, very sturdy, antiseize aluminum with tensile strength of 440MPa, which ensures perfect glide of the lever and central fastening rod in high tensile strength galvanized steel.Elastic elements in steel with a very high yield point and initial preload are inserted in the tensioners, ensuring the most constant pressure range possible. In addition, the specific mechanical properties of the material prevent wear on the elastic internal elements due to movement, so we are able to supply a product of absolute excellence in this field.

The load lever in galvanized steel is mounted on the end of the base cap.

The versatility of the TR models is due to the possibility to change the load lever so as to reach any height without losing in rigidity. They have interchangeable 110,111,115,118 levers for the type 1 and 210,218,227 levers for the type 2.

They are characterized in particular by the fact that O-rings are mounted on the inside to prevent infiltrations, so they have an excellent watertight seal.

All rotating TR tensioners have a tensioning angle of over 45° in both directions of rotation.

They are easy to install, because they can be fastened to the machine either with screws from the inside or from the outside, with rear stop slots to block rotation on imperfect or irregular surfaces.

They can be supplied with chain tensioning shoes in polyethylene 1,000,000 UHMW with dynamic dry steel friction coefficient 0,06, chain tensioning pinions, belt tensioning rollers and idle pulleys.

Datasheet